Description

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft or filling. (Weft or 'warrior ' is an old English word meaning "that which is woven".) The method in which these threads are inter-woven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band which meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, back-strap, or other techniques without looms.

Warp and weft in plain weaving

A satin weave, common for silk, each warp thread floats over 16 weft threads.

The way the warp and filling threads interlace with each other is called the weave. The majority of woven products are created with one of three basic weaves: plain weave, satin weave, or twill. Woven cloth can be plain (in one colour or a simple pattern), or can be woven in decorative or artistic design.

In general, weaving involves using a loom to interlace two sets of threads at right angles to each other: the warp which runs longitudinally and the weft (older woof) that crosses it. One warp thread is called an end and one weft thread is called a pick. The warp threads are held taut and in parallel to each other, typically in a loom. There are many types of looms.

Weaving can be summarized as a repetition of these three actions, also called the primary motion of the loom.

- Shedding: where the ends are separated by raising or lowering heald frames (heddles) to form a clear space where the pick can pass

- Picking: where the weft or pick is propelled across the loom by hand, an air-jet, a rapier or a shuttle.

- Beating-up or battening: where the weft is pushed up against the fell of the cloth by the reed.

The warp is divided into two overlapping groups, or lines (most often adjacent threads belonging to the opposite group) that run in two planes, one above another, so the shuttle can be passed between them in a straight motion. Then, the upper group is lowered by the loom mechanism, and the lower group is raised (shedding), allowing to pass the shuttle in the opposite direction, also in a straight motion. Repeating these actions form a fabric mesh but without beating-up, the final distance between the adjacent wefts would be irregular and far too large.

The secondary motion of the loom are the:

- Let off Motion: where the warp is let off the warp beam at a regulated speed to make the filling even and of the required design

- Take up Motion: Takes up the woven fabric in a regulated manner so that the density of filling is maintained

The tertiary motions of the loom are the stop motions: to stop the loom in the event of a thread break. The two main stop motions are the

- warp stop motion

- weft stop motion

The principal parts of a loom are the frame, the warp-beam or weavers beam, the cloth-roll (apron bar), the heddles, and their mounting, the reed. The warp-beam is a wooden or metal cylinder on the back of the loom on which the warp is delivered. The threads of the warp extend in parallel order from the warp-beam to the front of the loom where they are attached to the cloth-roll. Each thread or group of threads of the warp passes through an opening (eye) in a heddle. The warp threads are separated by the heddles into two or more groups, each controlled and automatically drawn up and down by the motion of the heddles. In the case of small patterns the movement of the heddles is controlled by "cams" which move up the heddles by means of a frame called a harness; in larger patterns the heddles are controlled by a dobby mechanism, where the healds are raised according to pegs inserted into a revolving drum. Where a complex design is required, the healds are raised by harness cords attached to a Jacquard machine. Every time the harness (the heddles) moves up or down, an opening (shed) is made between the threads of warp, through which the pick is inserted. Traditionally the weft thread is inserted by a shuttle.

On a conventional loom, the weft thread is carried on a pirn, in a shuttle that passes through the shed. A handloom weaver could propel the shuttle by throwing it from side to side with the aid of a picking stick. The "picking΅ on a power loom is done by rapidly hitting the shuttle from each side using an overpick or underpick mechanism controlled by cams 80–250 times a minute. When a pirn is depleted, it is ejected from the shuttle and replaced with the next pirn held in a battery attached to the loom. Multiple shuttle boxes allow more than one shuttle to be used. Each can carry a different colour which allows banding across the loom.

Weaving pattern cards used by Skye Weavers, Isle of Skye, Scotland

The rapier-type weaving machines do not have shuttles, they propel the weft by means of small grippers or rapiers that pick up the filling thread and carry it halfway across the loom where another rapier picks it up and pulls it the rest of the way. Some carry the filling yarns across the loom at rates in excess of 2,000 metres per minute. Manufacturers such as Picanol have reduced the mechanical adjustments to a minimum, and control all the functions through a computer with a graphical user interface. Other types use compressed air to insert the pick. They are all fast, versatile and quiet.

The warp is sized in a starch mixture for smoother running. The loom warped (loomed or dressed) by passing the sized warp threads through two or more heddles attached to harnesses. The power weavers loom is warped by separate workers. Most looms used for industrial purposes have a machine that ties new warps threads to the waste of previously used warps threads, while still on the loom, then an operator rolls the old and new threads back on the warp beam. The harnesses are controlled by cams, dobbies or a Jacquard head.

A 3/1 twill, as used in denim

The raising and lowering sequence of warp threads in various sequences gives rise to many possible weave structures:

- plain weave: plain, and hopsacks, poplin, taffeta,[8] poult-de-soie, pibiones and grosgrain.

- twill weave: these are described by weft float followed by warp float, arranged to give diagonal pattern. 2/1 twill, 3/3 twill, 1/2 twill. These are softer fabrics than plain weaves.,

- satin weave: satins and sateens,

- complex computer-generated interlacings.

- pile fabrics : such as velvets and velveteens

Both warp and weft can be visible in the final product. By spacing the warp more closely, it can completely cover the weft that binds it, giving a warp faced textile such as repp weave. Conversely, if the warp is spread out, the weft can slide down and completely cover the warp, giving a weft faced textile, such as a tapestry or a Kilim rug. There are a variety of loom styles for hand weaving and tapestry.

Equipment & Supplies

A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

Types of looms

Back strap loom

Woman weaving a silk rebozo on a backstrap loom at the Taller Escuela de Rebocería in Santa Maria del Rio, San Luis Potosí

A simple loom which has its roots in ancient civilizations consists of two sticks or bars between which the warps are stretched. One bar is attached to a fixed object, and the other to the weaver usually by means of a strap around the back. On traditional looms, the two main sheds are operated by means of a shed roll over which one set of warps pass, and continuous string heddles which encase each of the warps in the other set. The weaver leans back and uses their body weight to tension the loom. To open the shed controlled by the string heddles, the weaver relaxes tension on the warps and raises the heddles. The other shed is usually opened by simply drawing the shed roll toward the weaver. Both simple and complex textiles can be woven on this loom. Width is limited to how far the weaver can reach from side to side to pass the shuttle. Warp faced textiles, often decorated with intricate pick-up patterns woven in complementary and supplementary warp techniques are woven by indigenous peoples today around the world. They produce such things as belts, ponchos, bags, hatbands and carrying cloths. Supplementary weft patterning and brocading is practiced in many regions. Balanced weaves are also possible on the backstrap loom. Today, commercially produced backstrap loom kits often include a rigid heddle.[citation needed]

Warp-weighted loom

The warp-weighted loom is a vertical loom that may have originated in the Neolithic period. The earliest evidence of warp-weighted looms comes from sites belonging to the Starčevo culture in modern Serbia and Hungary and from late Neolithic sites in Switzerland.[4] This loom was used in Ancient Greece, and spread north and west throughout Europe thereafter.[5] Its defining characteristic is hanging weights (loom weights) which keep bundles of the warp threads taut. Frequently, extra warp thread is wound around the weights. When a weaver has reached the bottom of the available warp, the completed section can be rolled around the top beam, and additional lengths of warp threads can be unwound from the weights to continue. This frees the weaver from vertical size constraints.

Drawloom

A drawloom is a hand-loom for weaving figured cloth. In a drawloom, a "figure harness" is used to control each warp thread separately.[6] A drawloom requires two operators, the weaver and an assistant called a "drawboy" to manage the figure harness. The earliest confirmed drawloom fabrics come from the State of Chu and date c. 400 BC.[7] Most scholars attribute the invention of the drawloom to the ancient Chinese, although some speculate an independent invention from ancient Syria since drawloom fabrics found in Dura-Europas are thought to date before 256 AD.[7][8] The draw loom for patterned weaving was invented in ancient China during the Han Dynasty.[9] Chinese weavers and artisans used foot-powered multi-harness looms and jacquard looms for silk weaving and embroidery; both of which were cottage industries with imperial workshops.[10] The Chinese-invented drawloom enhanced and sped up the production of silk and play a significant role in Chinese silk weaving. The loom was later introduced to Persia, India, and Europe.[11]

Handloom

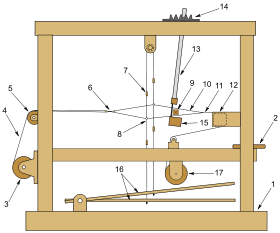

Elements of a foot-treadle floor loom

- Wood frame

- Seat for weaver

- Warp beam- let off

- Warp threads

- Back beam or platen

- Rods – used to make a shed

- Heddle frame - heald frame - harness

- Heddle- heald - the eye

- Shuttle with weft yarn

- Shed

- Completed fabric

- Breast beam

- Batten with reed comb

- Batten adjustment

- Lathe

- Treadles

- Cloth roll- takeup

A handloom is a simple machine used for weaving. In a wooden vertical-shaft looms, the heddles are fixed in place in the shaft. The warp threads pass alternately through a heddle, and through a space between the heddles (the shed), so that raising the shaft raises half the threads (those passing through the heddles), and lowering the shaft lowers the same threads — the threads passing through the spaces between the heddles remain in place. This was a great invention in the 13th century.

Flying shuttle

Main article: Flying shuttle

Hand weavers could only weave a cloth as wide as their armspan. If cloth needed to be wider, two people would do the task (often this would be an adult with a child). John Kay (1704–1779) patented the flying shuttle in 1733. The weaver held a picking stick that was attached by cords to a device at both ends of the shed. With a flick of the wrist, one cord was pulled and the shuttle was propelled through the shed to the other end with considerable force, speed and efficiency. A flick in the opposite direction and the shuttle was propelled back. A single weaver had control of this motion but the flying shuttle could weave much wider fabric than an arm’s length at much greater speeds than had been achieved with the hand thrown shuttle.

The flying shuttle was one of the key developments in weaving that helped fuel the Industrial Revolution. The whole picking motion no longer relied on manual skill and it was just a matter of time before it could be powered.

Haute-lisse and basse-lisse looms

Looms used for weaving traditional tapestry are classified as haute-lisse looms, where the warp is suspended vertically between two rolls. In basse-lisse looms, however, the warp extends horizontally between the two rolls.

Ribbon weaving

Main article: Inkle weaving

Traditional looms

Several other types of hand looms exist, including the simple frame loom, pit loom, free-standing loom, and the pegged loom. Each of these can be constructed, and provide work and income in developing societies

Time Commitment

Cost

Skills Needed

Skills Developed

This article uses material from the Wikipedia article "", which is released under the Creative Commons Attribution-Share-Alike License 3.0.

Resources

Associations & Organizations

Blogs & Forums

Books & magazines

Videos

Websites

Social Media Networks

Flickr

Google+

Kik

Medium

Periscope

Shots

Snapchat

SoundCloud

Swarm by Foursquare

tinder

Tumblr

YouTube

Members Only Area

Here is where you find more resources. Including schools, instructors, tour and guide operators. many within your local areas.

You will also find